Hydraulic hoses »pressed«

All hoses listed here are already pressed, pre-assembled on both sides and available from stock.

| 8 mm pipe | nominal diameter 6 | (2SC, 250 bar operating pressure / SW 17) |

| 10 mm pipe | nominal diameter 8 | (2SC, 250 bar operating pressure / SW 19) |

| 12 mm pipe | nominal diameter 10 | (2SC, 250 bar operating pressure / SW 22) |

| 15 mm pipe | nominal diameter 12 | (2SC, 250 bar operating pressure / SW 27) |

| 18 mm pipe | nominal diameter 16 | (2SC, 160 bar operating pressure / SW 32) |

| 22 mm pipe | nominal diameter 20 | (2SC, 160 bar operating pressure / SW 36) |

SW = wrench size

| EN 857/2SC, 2SC Compact |

Caution

|

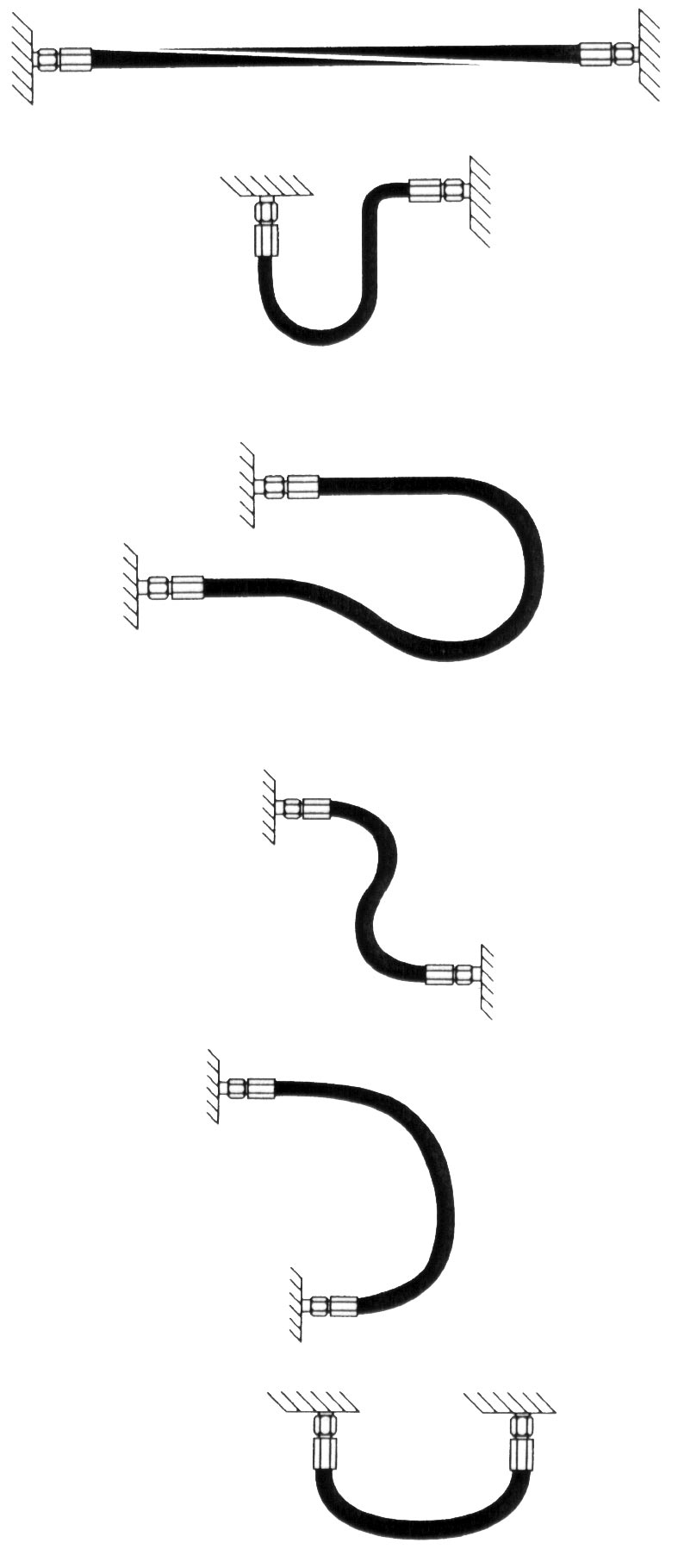

| WRONG |

|

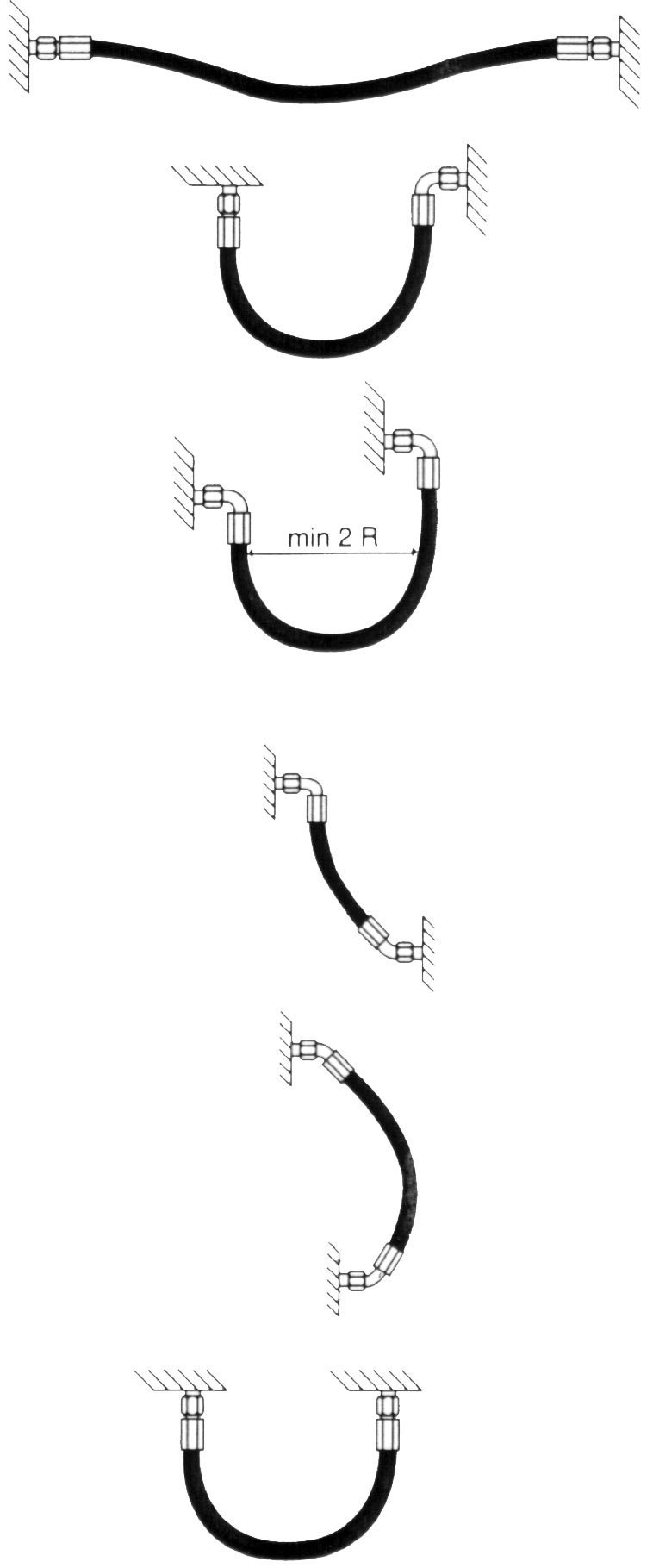

| RIGHT |

|

| Instructions for installation |

Correct Installation increases the service life of hose assemblies!

|

+49 (0) 8671 / 9600 - 0 (Mo-Fr 8:00 -18:00 Uhr & Sa 8.00-12.00)

+49 (0) 8671 / 9600 - 0 (Mo-Fr 8:00 -18:00 Uhr & Sa 8.00-12.00)